Choosing the right industrial mezzanine flooring is just one aspect of the design process when it comes to a mezzanine system, and there are many factors to help make the correct design choice. Factors such as what is being stored on the industrial mezzanine, as well as budget, and over-all aesthetic look of the system.

What is an Industrial Mezzanine?

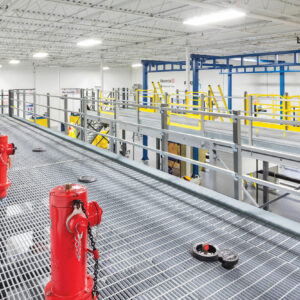

An industrial mezzanine is a steel platform and flooring system installed as an additional level inside a warehouse. The structural aspects of a warehouse mezzanine include solid steel vertical posts, horizontal I-beams, and support trusses.

The structural system is then outfitted with a flooring material which we will delve into deeper below. Finally, the mezzanine is complete with safety fencing around the entirety of the platform, to ensure the security of warehouse employees, machinery and products from falling over the edge.

Types of Industrial Mezzanine Flooring:

There are a few options when it comes to choosing the right industrial mezzanine floor. Option include bar grating, metal decking or more commonly synthetic plywood. Sometimes, industrial mezzanines will be completed with concrete flooring; however, this does impede the ability to move the mezzanine in the future.

Bar grating as a mezzanine floor can be easily installed, and scaled to fit any industrial mezzanine. With its robust design, bar grating and withstand almost any load weight, and is virtually maintenance free.

Another great advantage is that bar grating allows for the passage or air, light and heat.

Synthetic Plywood (ResinDek)

Synthetic plywood (ResinDek) panels made of wood fibers and resin, and are a popular choice among mezzanine flooring. The panels are a great choice for their strength and durability.

The panels are specifically designed for industrial mezzanine floors, and are therefore built to withstand forklifts, pallet jacks, rolling carts, autonomous mobile robots (AMR) and automated guarded vehicles (AGV).

Metal Decking (Metagard)

Steel metal decking (Metagard) is often used on industrial mezzanine floors because of their durability. An entire mezzanine floor may be surfaced with metal decking, or sometimes metal decking is only partially used on high traffic areas, to cut costs.

These places are typically drop-off zones, where pallets get dragged across the floor, which causes damage to floor panels. Also, metal decking is used in areas where autonomous mobile robots (AMRs) are used, since the continuous use of this equipment does cause wear and tear.

Concrete

A concrete floor is a great choice for an industrial mezzanine floor because it is the most durable of all flooring types. However, concrete flooring is heavy, and with a concrete floor the mezzanine becomes permanent, whereas with other types of flooring, a mezzanine is typically modular, and scalable.

For all your other questions about an industrial mezzanines, and the benefits that it can serve you and your warehouse, contact one of our experts today!

by

by