VERTICAL LIFT MODULES

Vertical Lift Modules (VLMs) are fully automated storage systems that allow for minimal space impact by taking up vertical space, which is otherwise difficult to access. They consist of a series of trays or carriers that move vertically within an enclosed unit, delivering stored items to an access point. VLMs use an inserter/extractor within the unit which locates the desired stored tray.

Custom vertical lift modules for optimized storage are available in a wide range of sizes and capacities to suit your specific needs.

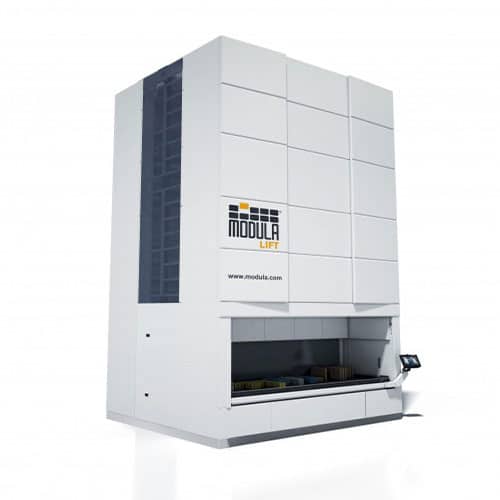

Concept Storage Solutions is a proud integrator of Modula Lift Products. Browse Modula’s VLM models below, and speak to a team member today to learn more!

MODULA VERTICAL LIFT MODULES

- Modula Lift

- Modula Slim

- Modula OnePick

The Modula Lift is the ideal storage solution for industrial products, components and spare parts for all possible environments and industries. You can store almost any type of equipment on the shelves such as carton boxes, plastic moulds, automotive parts and manufacturing supplies. It is tough as nails with a throughput of up to 130 trays per hour, and a tray payload capacity of up to 2,200 lbs. These Vertical Lift Systems have the capability to reduce space requirements by up to 90%, while increasing speed, efficiency and accuracy of picking operations.

——————————

Unit heights

10’10” – 52’10”

(3,300 – 16,100 mm)

Net tray payload options

551-2,182 lbs.

(250-990 kg)

Tray widths

59, 75, 98, 122 or 161″

(1,500,1,900, 2,500, 3,100 or 4,100 mm)

The Modula Slim is the most compact VLM on the market. The Modula slim can store many different types of materials and products including containers (boxes, bins, cartons, and cases), small items, spare parts, coils, bottles, loose material and more. This solution is perfect for warehouses with limited floor space, and with its compact nature, the Modula Slim only requires 32.29 square feet of floor space. The Modula Slim is built on a pre-assembled-based module that ships quickly, so you can have your automated picking system up and running as soon as possible. It’s also easy to bring online and connect with your company’s existing inventory management systems.

——————————

Unit heights

7’11” – 22’12”

(2,400-7000 mm)

Net tray payload options

771.68 lbs.

(350 kg)

Tray widths

51, 75, 98″

(1,300, 1,900 or 2,500 mm)

The Modula OnePick is an industrial storage solution of truly sophisticated technology. This VLM has a robotic system to pick places and boxes and therefore runs without an operator. The Modula OnePick can be integrated with your current conveyor belts, rollers, AGVs, and AGCs.

——————————

Unit heights

10’10″” – 46’3″

(3,300-14,100 mm)

Net tray payload options

551-2,182 lbs.

(250 – 990 kg)

Tray widths

75-161″

(1,900 – 4,100 mm)

VERTICAL LIFT MODULES APPLICATIONS

VERTICAL LIFT MODULES BENEFITS

Space Optimization

Maximizing vertical space, VLMs allow for more storage in a smaller footprint, reducing the need for extensive floor space.

Improved Efficiency & Organization

Utilizing automated storage processes saves time, reducing labor costs, and increasing productivity. Items are stored and retrieved efficiently, reducing errors and streamlining inventory management.

Safety & Security

VLMs bring items to a comfortable, ergonomically appropriate height, reducing the risk of workplace injuries. VLMs are equipped with secure access controls, safeguarding valuable and sensitive items.

Inventory Control & Access

Better organization and tracking of inventory lead to improved accuracy and a decrease in stockouts or overstock situations. Items are delivered to the operator at the touch of a button, reducing weight times and improving order fulfillment.

Customization and Adaptability

Tailored to meet specific storage needs, VLMs accommodate a wide range of items, shapes, and sizes. Automated technologies can be integrated with warehouse management systems and make operations seamless.

by

by