1. Gather Equipment a. Level b. Shims c. Hammer Drill d. Concrete Drilling Bit e. Vacuum/shop-vac/wire brush f. Wedge Anchors g. Hammer h. Impact Driver |

2. Level Frames |

3. Drill Hole |

4. Clear Hole |

5. Insert Anchor |

6. Tighten Nut |

What are Wedge Anchors?

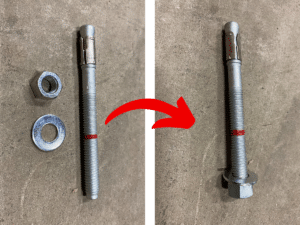

Wedge anchors are steel bolts that are installed in pre-drilled holes to secure pallet racking frames (uprights) to concrete flooring. At face value, the wedge anchors look like your typical bolt-nut-washer set. However, what makes wedge anchors unique are their tapered ends. When the bolt is in the concrete, it is then tightened which causes the threads of the bolt to move upward through the nut. The tapered end is then forced through a metal sleeve (otherwise known as an expansion clip). This increases the space the wedge anchor is taking up inside of the concrete and thus secures it in place. Similar to how a drywall anchor works!

Wedge anchors come in a variety of different lengths and diameters. The larger the diameter, the longer the wedge anchor is, and thus the stronger it is. It is very important to consult a professional engineer to understand what size wedge anchor is required for a particular racking system.

The most common wedge anchor sizes are:

- 1/4” x 2 1/4”

- 1/2” x 4-1/2”

- 3/8” x 3”

- 5/8” x 4-1/2”

When to use Wedge Anchors

Pallet racks will be ready for anchoring after the uprights and horizontal beams have been assembled, and are in the correct place. A warehouse layout or a drawing is very important in this step to ensure that the pallet racking system is installed correctly.

Once the frames are anchored, the wedge cannot be removed from the concrete. If the racks needed to be moved, the wedge anchor would need to be cut. Therefore, anchoring is one of the last steps in the installation process of a selective pallet racking project.

Anchoring after the uprights and horizontals are in place provides a safety net in case a measurement was slightly off.

Like any construction project, careful planning and preparation beforehand will benefit you in the long run. It is paramount that you, or your pallet racking installation team, have the expertise and equipment to get the job done correctly, efficiently and safely.

How to Anchor Pallet Racks to Concrete Flooring:

1. Ensure you have the following equipment

- Level

- Shims

- Hammer Drill

- Concrete Drilling Bit

- Vacuum/shop-vac/wire brush (for cleaning the hole)

- Wedge Anchors

- Hammer

- Impact Driver with a properly sized socket for your anchors (a socket wrench could also work)

2. Level your Frames

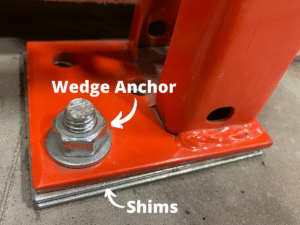

It is common that warehouse concrete floors are not perfectly level. In this instance, you can use shims (typically they are steel, or plastic) to get your uprights in a level position. If you fail to level your uprights, this will greatly affect the integrity of your racking system.

Once you have ensured that your frame is level, you are ready to drill!

3. Drill Hole

There are typically two to three holes on each base plate, but in most cases, you will only need one anchor per vertical post (so two anchors total per frame). If this is the case, stagger the anchors so that you are not using the identical hole on each base plate of the frame.

There are instances where two or more wedge anchors are required per base plate. This is common for pallet racking that will be storing a large amount of weight, or if the pallet racking is in a location where seismic activity is common. Consult your engineer or safety officer to know how many wedge anchors are required for your pallet racking.

Drill through the baseplate hole of the upright using a drill bit of the same size as your wedge anchors. The hole should go deeper than the length of your wedge anchor – see table below. However, it is best to consult a professional engineer to know the correct hole-depth required.

Once you are sure of the correct hole-depth, you can set a depth gauge on your hammer drill, or use the age old trick of taping the bit.

The depth of the hole that you must drill will be based on the wedge anchor diameter.

| Wedge Anchor Diameter | Minimum Hole Depth* |

| 3/8” | 2” |

| 1/2” | 2-5/8” |

| 5/8” | 3-3/4” |

| 3/4” | 4” |

Source: Hilti.ca

*These depths are only a suggestion, it is best to consult an engineer to get the most accurate hole-depth required.

INSTALLATION

Whether you are expanding your warehouse, moving, or modifying your existing warehouse storage systems, we provide expert pallet racking installation services.

Learn MoreACCESSORIES

There's a lot more to pallet racking than beams and frames! We maintain a large stock of pallet racking accessories including safety bars, wire mesh decking, row spacers, post protectors & more!

Learn More4. Clear Hole

Using a vacuum and/or wire brush, give the hole a cleaning. Clearing the hole will allow the anchor to grip the concrete better.

5. Insert Anchor

Slide a washer onto the anchor, and thread the nut so that it is flush with the top of the bolt. Next, place the wedge anchor into the hole you have drilled. Using your hammer, drive it down until the nut connects with the base plate.

6. Tighten Nut

Using an impact driver, or a socket wrench, tighten the nut. You will want to tighten it best you can but be careful not to over torque it (see torque value chart below). You will see the anchor pull upwards as the nut tightens.

| Wedge Anchor Diameter | Torque Value (ft-lb) |

| 3/8” | 25 |

| 1/2” | 40 |

| 5/8” | 60 |

| 3/4” | 110 |

Source: Hilti.ca

And there you have it – your pallet racking is anchored to your floor!

Importance of Anchoring your Pallet Racks

Pallet rack storage systems must be anchored to the floor to ensure the maximum stability and security of the system. When installed properly, storage systems are designed to withstand unexpected forces like earthquakes, and (more commonly experienced) accidents caused by forklifts. Anchoring your pallet racking will ensure that when these inevitable events occur, your pallet rack will remain secure. Should your upright frames shift after an event like a forklift accident, this could cause a system collapse. When pallet racking is anchored properly, a forklift accident may still cause damage to the system, but will seldom cause a catastrophe like a full system failure.

by

by